Thursday, December 6, 2012

I've Moved - New Blog Address

I've had a new website and blog designed thanks to Candour - purveyors of strategic branding and graphic design. Click on over and check out www.MeaganChaneyGumpert.com. There's a tab for my blog page.

If you've been following along with me through an RSS feed, this should have transferred to my new page, but if you're missing out, just let me know and we'll see if we can get the situation resolved.

Cheers!

Friday, October 5, 2012

Low Fire Friday - Glaze layering (Guest Artist Martina Lantin)

I had the pleasure of meeting Martina while we were teaching at Arrowmont School of Arts and Crafts this past August. Though I've know her work for awhile, it's always great to meet the maker behind the handmade. Instantly, I was won over by her easy going, but professional nature and enjoyed conversations we had in and out of the studio all week.

Born in Montreal,

Canada, Martina Lantin received her Bachelor of Art from Earlham College (1996)

and her Master of Fine Art from NSCAD University (2009). She has been an artist in residence at

Baltimore Clayworks in Baltimore, MD and Arrowmont School of Art and Craft in Gatlinburg,TN. Currently, Martina is a professor at

Marlboro College in Marlboro, VT.

Selected as an

Emerging Artist by Ceramics Monthly (2002), her work has been recognized in

numerous juried and invitational exhibitions. In 2010 Martina

was award an Individual Artist Grant by the Tennessee Arts Commission. She has also published articles in both Studio Potter and Pottery Making Illustrated.

Here are the low fire glazes and application technique Martina is sharing with us today:

WOODY HUGHES BASE GLAZE – CONE 04 – good

with colorants

Gerstley Borate

|

26

|

Lithium

Carbonate

|

4

|

Frit 3124

|

30

|

NephalineSyenite

|

20

|

EPK

|

10

|

Flint

|

10

|

Colorants can be

metallic oxides or carbonates or mason stains, singly or in combination.

Colors in the

image:

Blue green: 2% copper carbonate and 3% deep orchid stain

Violet: 5% orchid stain and 1.5% rutile

OPAQUE GLOSS: (rated for cone 015 – as an over-glaze enamel)

Frit 3134

|

36.4

|

Pemco ‘P-25’

(frit 3269)

|

55.6

|

EPK

|

8

|

Add tin

|

10

|

Colorants –

stains or oxides. Do your own tests to

develop your palette – start with 2 – 10 %

First, the Opaque Gloss is slip trailed onto the piece (in the example photo - the colors you see are from the slip decoration applied prior to bisquing). Spaces in the design motif can be filled in with colored versions of the Woody Hughes base (brush application works best for filling in areas with color). Woody Hughes base glaze is applied to cone 05 bisqueware, ideally poured or dipped.

You can also play with waxing over the colored Woody's glazes or not – depending on the fluidity desired. The clear Woody's Base glaze can be very thin for dipping, however when the stains or oxides are added for the colored glazes, thicker is better for brushing purposes.

Martina then fires to cone 03 using a kiln sitter or cone 04 when using a computer program with cone 04 on the program and 25 minute hold at the end.

So, there you have it! Martina let us in on some of the secrets of how she gets such beautiful, fluid results in her work!

Hope you're having a wonderful Friday!

Meagan

First, the Opaque Gloss is slip trailed onto the piece (in the example photo - the colors you see are from the slip decoration applied prior to bisquing). Spaces in the design motif can be filled in with colored versions of the Woody Hughes base (brush application works best for filling in areas with color). Woody Hughes base glaze is applied to cone 05 bisqueware, ideally poured or dipped.

You can also play with waxing over the colored Woody's glazes or not – depending on the fluidity desired. The clear Woody's Base glaze can be very thin for dipping, however when the stains or oxides are added for the colored glazes, thicker is better for brushing purposes.

Martina then fires to cone 03 using a kiln sitter or cone 04 when using a computer program with cone 04 on the program and 25 minute hold at the end.

So, there you have it! Martina let us in on some of the secrets of how she gets such beautiful, fluid results in her work!

Hope you're having a wonderful Friday!

Meagan

Sunday, September 16, 2012

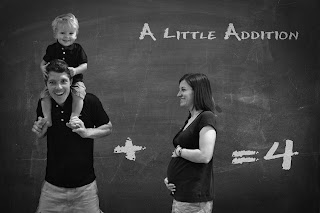

Our New Addition

I'm happy to announce that Fletcher Elliot was born Thursday, September 6 at 9:23 am weighing 6lbs 11oz and 20" long. We had another wonderful, natural birth. Hooray!

We are all doing well and are settling into life as a family of four. Even Big Brother Cooper

Cheers!

Friday, September 7, 2012

Low Fire Friday - Amaco Velvet Underglazes

In the ceramic studio we tackled making 100+ mugs that would be left in the dining hall for student use during the course of Arrowmont's one-week workshops. Most of the mugs that resulted from this exciting project were touched by multiple hands. Someone would throw/trim the mug, someone else would add a handle, then it would get passed along for decoration/surface design. After it was bisque fired, someone else would apply the final glaze and then it was off to get fired again.

During the course of this process, I found myself as a "decorator" and discovered a new obsession - Amaco Velvet Underglazes!

Here is the finished Arrowmont Official Birthday Mug. I wish I could report who made the mug and who added the handle, but Brian Hiveley did the carving and illustration and I worked on the underglazes.

The underglazes were applied to greenware. After bisque firing, a black mason stain wash was applied and then a clear glaze was applied over the entire surface.

The underglazes were applied to greenware. After bisque firing, a black mason stain wash was applied and then a clear glaze was applied over the entire surface. |

| Look at the amazing color range available from Amaco! |

The color palette in my work has been getting brighter and brighter over the years. (Possibly coinciding with living in Florida?) And I'm now finding that these underglazes are just what I was looking for to add that extra pop of color and still allow me to get a smooth gradation I've been wanting.

|

| Invigorate, earthenware and kiln cast glass, 16" x 13" x 7" |

I doubt I've given up my crunchy, crawly glazes, but this new direction excites me! And for those reading who may not be into mixing their own glazes, I thought it would be helpful to know some great commercial glaze options.

Cheers!

Friday, August 24, 2012

Low Fire Friday: Bonus Edition - Reader Results with Crawl

I recently received an exciting email from a reader who has been working with the Low Fire Crawl glaze I featured in January's Low Fire Friday segment.

Rand O'Brien from New Hampshire writes:

"I have been using

your Magnesium crawl in raku with wonderful results. The spaces between

the beads seal against carboning and the beads "stick" very

well. Your dark Turquoise develops a beautiful luster in

reduction."

Here's a re-posting of the Low Fire Crawl recipe Rand is referring too:

Crawl Glaze - Cone 04

Gerstley Borate 46.5

Magnesuim Carbonate 31.0

EPK 18.6

Borax 3.9

______________________

100.0

+ Zircopax 5.5

For color add...

Beige/pale yellow: + red iron oxide 1%

Dark turquoise/jade: + copper carbonate 5%

Light turquoise/jade: + copper carbonate 1%To see glaze test tiles of this recipe fired to cone 04 check out the original LFF post.

Rand, Thank you so much for sharing your results! That luster halo with the turquoise is amazing!

If anyone else has tried any of the Low Fire Friday glazes and would like to share how they've worked for you, email me at info@MeaganChaney.com and I'll be happy to put together a Bonus Edition featuring your work.

Cheers!

Meagan

Friday, August 3, 2012

Low Fire Friday - A brief into to glazes and glaze mixing

Glaze – A Brief Intro

A glaze is glassy

substance that has been adhered to the surface of ceramics through firing. It

is made up of a glass former, a stabilizer and a flux.

The glass former

is the glass. Typically this will be in the form of silica/flint

The stabilizer is

what keeps the glass from completely running off of the ceramic piece.

Alumina is the main stabilizer and is found in clay.

The flux is an

oxide (generally Alkaline) which causes ceramic fusion

when combined with other oxides and heated.

Glaze recipes are

usually written as a list with ingredients totaling 100%. This base glaze is

usually clear/white. Any colorants, opacifiers, suspenders, and gums are written below the 100% line and are added as a percentage of the

total glaze.

Base 4

|

||

Base Glaze

|

Frit 3195

|

65

|

Gerstly Borate

|

10

|

|

Wollastonite

|

15

|

|

EPK

|

10

|

|

100

|

||

Bentonite

|

2

|

|

Colorants

|

||

Dark Brown

|

Red Iron Oxide

|

10

|

Glazes are usually measured and mixed by weight. However,

any unit of weight can be used as long as it is constant throughout the entire

recipe. I weigh my materials out in grams and typically mix a 500g batch (about the size of a large yogurt container). This

means that I would multiply each material the recipe by 5.

So, I would actually be measuring and mixing the above

recipe like this…

Base 4

|

|||

Base Glaze

|

Frit 3195

|

65

|

325g

|

Gerstly Borate

|

10

|

50g

|

|

Wollastonite

|

15

|

75g

|

|

EPK

|

10

|

50g

|

|

100

|

500g

|

||

Bentonite

|

2

|

10g

|

|

Colorants

|

|||

Dark Brown

|

Red Iron Oxide

|

10

|

50g

|

Water is added until the desired consistency is reached. This is a matter of preference and application technique. I brush my glazes on super, SUPER thick, so my glazes are usually about the consistency of Greek yogurt.

I hope this answered a few of your questions and will help get you started if you're new to glaze mixing. If you have any other questions, please feel free to comment or email me.

Cheers!

Meagan

Friday, July 6, 2012

Low Fire Friday - Base 3

Recently, I've been doing a lot of tests and line blends looking for a

reliable, food-safe, base glaze that works well with Mason Stains. And I

think I just may have found one that suits my needs!!

Base 3 has a glossy surface, though not super crazy shiny. It's a bit semi-opaque with lower percentages of stains, and becomes opaque when higher percentages are added.

Base 3 - Cone 04

Base 3 has a glossy surface, though not super crazy shiny. It's a bit semi-opaque with lower percentages of stains, and becomes opaque when higher percentages are added.

Base 3 - Cone 04

Frit 3134 75

EPK 15

Silica 10

__________________

100

Bentonite 2%

For color add...

The Mason Stains I've tested are:

- #6236 - Chartreuse

- #6026 - Lobster

- #6379 - Robins Egg

- #6025 - Coral Red

- #6201 - Celadon

I mixed up a 100g batch of Base 3 for each of the above Mason Stains. (That's five separate 100g batches.) For each batch I started by adding 1% Mason Stain, or 1g. Then, to test how the glaze would look with 3% Mason Stain, I added 2g. Yes, only 2g because my 100g test batch already has 1g in it. For a 5% Mason Stain, I then only needed to add another 2g, and so on. It can get tricky so I always write all this down before I get started. Between each addition I brush a stripe on my test tile before moving on and adding more Stain.

I tested each Stain at 1%, 3%, 5%, 8%, 10%, 12%, 15%, 18%, and 20%. Some of the differences are too subtle to see in these images, but are more viable in person.

This will give you a nice range of color saturation for each Stain. From these results you can decide what you like and do further testing if desired.

So, for example, if you like the color/look of the third stripe from the left on the Celadon Line Blend, then you would mix up the Base glaze with the addition of the 2% Bentonite and then 5% Mason Stain #6201 - Celadon.

I've labeled each image with the Mason Stain used and tried to test all colors on both red and white clay. (Though you can see the state of some of my test tiles is a bit rough and I'm missing red clay samples for the Lobster Stain and Chartreuse Stain.)

Lots of testing, but if you're (crazy) like me, you love this part of the process! If you've got questions, just leave a comment or shoot me an email.

Well, happy glaze testing.

Meagan

Friday, June 1, 2012

Low Fire Friday - Lizard Skin Glaze

Lizard Skin - Cone 04

Magnesium Carbonate 40

Lithium Carbonate 15

Borax 10

Gerstley Borate 20

Silica 5

Nepheline Syenite 20

___________________

110

For color add...

Light golden brown/dark yellow ochre: + Rutile 5%

NOTES:

Lizard Skin has a sandier,

crunchier texture compared to the smooth satin beads of the Low Fire Crawl Glaze. Again, apply it THICK.

With

this glaze, I've had the best results using it immediately after it has

been mixed. Probably from the Borax (which is water soluble and

evaporates changing the composition of the glaze) and from the Neph Sye

(which causes the glaze to settle like a rock making remixing

difficult.)

Thursday, May 31, 2012

Newest Wall Sculptures - Spring 2012

Is tomorrow really, June 1st? Where does the time go?

In late March I was contacted by Harris Warren Gallery in Wake Forest, NC and arrangements were quickly made for a June exhibition. Well, here we are - Goodbye Spring. Hello Summer. It's been a whirlwind, but I'm proud to say that I completed 4 new wall sculptures for my show "Variegated Disposition" opening next Friday, June 8, 2012.

In addition to these, I'll also have 4 other works on exhibit. If you're in the area, please stop by.

Oh yeah, and there's one other work in progress...

Baby #2 (aka "Peanut") is due in September.

What an exciting Spring it's been indeed! Now onto surviving the hot Summer months of Florida!

Cheers!

Meagan

In late March I was contacted by Harris Warren Gallery in Wake Forest, NC and arrangements were quickly made for a June exhibition. Well, here we are - Goodbye Spring. Hello Summer. It's been a whirlwind, but I'm proud to say that I completed 4 new wall sculptures for my show "Variegated Disposition" opening next Friday, June 8, 2012.

|

| Anthocyanin, earthenware, 27” x 38” x2", May 2012 |

|

| Continuation, earthenware, 31" x 35" x 2", May 2012 |

|

| Dissipate, earthenware, 30" x 12" x 2", May 2012 |

|

| Provide, earthenware and cast glass, 27" x 15" x 2", May 2012 |

In addition to these, I'll also have 4 other works on exhibit. If you're in the area, please stop by.

Oh yeah, and there's one other work in progress...

Baby #2 (aka "Peanut") is due in September.

What an exciting Spring it's been indeed! Now onto surviving the hot Summer months of Florida!

Cheers!

Meagan

Friday, May 4, 2012

Low Fire Friday - Recycled Raku (Guest Artist John Britt)

This month's Guest Artist is none other than the Glaze Guru John Britt.

I took John's Basic Glaze Chemistry and Raw Materials workshop a few years ago, and let me tell you, it was AMAZING! This man is a walking glaze encyclopedia! I didn't think it was possible to learn so much information in such a short amount of time. Before I took John's class, I could follow a glaze recipe (ie measure and mix the listed ingredients) but if something went wrong, or I wanted to change something, I had NO IDEA how to proceed. It was like baking without knowing what flour, sugar and baking soda do. But after John's class, I had a much, much clearer understanding of what was happening and a great foundation for building my glaze palette.

John has been a potter and teacher for over 26 years. He lives in mountains of western North Carolina although he grew up in Dayton, Ohio. John is primarily a self-taught potter who has worked and taught at universities, colleges and craft centers across the country, including the Penland School of Crafts where he served as the Clay Coordinator and then, as the Studio’s Manager.

He is the author of the “The Complete Guide to High-Fire Glaze; Glazing & Firing at Cone 10” which was published by Lark Books in 2004, was the juror for the book; “500 Bowls”, Technical Editor for “The Art and Craft of Ceramics”, and has written numerous articles for ceramics publications including: Ceramics Monthly, Ceramic Review, Studio Potter, Clay Times, New Ceramics, Ceramic Technical and The Log Book.

He is currently a studio potter in Bakersville, North Carolina and teaches glaze chemistry, throwing, glazing and firing workshops.

Here is the glaze (and fun story) that John is sharing with us today...

Recycled Raku

This is one of my favorite chairs. I formed it with the wire cut method, where you take a block of clay

and cut out the chair shape. (http://www.youtube.com/watch?v=gvfyD5xJobI)

Then I bisque fired the chair to cone 05. Then I rakued it with the glaze Raku Turquoise:

Raku Turquoise (From Chappell’s Book)

42.5 Frit P-25

27.4 Frit 3134

14.0 Silica

9.8 Lithium carbonate

6.3 EPK

4.5 Copper Carbonate

2.0 Bentonite

Then what happened is that the front legs broke off as I was putting it in the Raku cans to smoke it. So after about a half of an hour I open the cans and the legs were kind of stuck together and messed up a bit. But rather than throw entire chair away I separated and reglazed the legs but refired them in an electric kiln to cone 05. This made the legs a copper blue while the main chair was more turquoise and copper.

I then glued them back on and this became my favorite chair because it had the interplay of the

different glazes within the same piece.

I took John's Basic Glaze Chemistry and Raw Materials workshop a few years ago, and let me tell you, it was AMAZING! This man is a walking glaze encyclopedia! I didn't think it was possible to learn so much information in such a short amount of time. Before I took John's class, I could follow a glaze recipe (ie measure and mix the listed ingredients) but if something went wrong, or I wanted to change something, I had NO IDEA how to proceed. It was like baking without knowing what flour, sugar and baking soda do. But after John's class, I had a much, much clearer understanding of what was happening and a great foundation for building my glaze palette.

|

| Just a few of the Cone 04 glaze tests from John's Basic Glaze Chemistry Class |

John has been a potter and teacher for over 26 years. He lives in mountains of western North Carolina although he grew up in Dayton, Ohio. John is primarily a self-taught potter who has worked and taught at universities, colleges and craft centers across the country, including the Penland School of Crafts where he served as the Clay Coordinator and then, as the Studio’s Manager.

He is the author of the “The Complete Guide to High-Fire Glaze; Glazing & Firing at Cone 10” which was published by Lark Books in 2004, was the juror for the book; “500 Bowls”, Technical Editor for “The Art and Craft of Ceramics”, and has written numerous articles for ceramics publications including: Ceramics Monthly, Ceramic Review, Studio Potter, Clay Times, New Ceramics, Ceramic Technical and The Log Book.

He is currently a studio potter in Bakersville, North Carolina and teaches glaze chemistry, throwing, glazing and firing workshops.

Here is the glaze (and fun story) that John is sharing with us today...

Recycled Raku

This is one of my favorite chairs. I formed it with the wire cut method, where you take a block of clay

and cut out the chair shape. (http://www.youtube.com/watch?v=gvfyD5xJobI)

Then I bisque fired the chair to cone 05. Then I rakued it with the glaze Raku Turquoise:

Raku Turquoise (From Chappell’s Book)

42.5 Frit P-25

27.4 Frit 3134

14.0 Silica

9.8 Lithium carbonate

6.3 EPK

4.5 Copper Carbonate

2.0 Bentonite

Then what happened is that the front legs broke off as I was putting it in the Raku cans to smoke it. So after about a half of an hour I open the cans and the legs were kind of stuck together and messed up a bit. But rather than throw entire chair away I separated and reglazed the legs but refired them in an electric kiln to cone 05. This made the legs a copper blue while the main chair was more turquoise and copper.

I then glued them back on and this became my favorite chair because it had the interplay of the

different glazes within the same piece.

Friday, April 6, 2012

Low Fire Friday - Bleeding Cake Glaze (Crunchy texture)

Another reliable glaze that works best if applied thick. Bleeding Cake is an opaque glaze with a crunchy, sandy texture.

Bleeding Cake - Cone 04

Volcanic Ash 33

Borax 20

Sand* 16 * (I use the fine grain hobby sand from Michael's or other craft store)

Grolleg 11

EPK 20

____________

100

[dark blue, moss green, brick red, yellow ochre]

For color add...

Dark blue: + Cobalt Carbonate 3%

Volcanic Ash 33

Borax 20

Sand* 16 * (I use the fine grain hobby sand from Michael's or other craft store)

Grolleg 11

EPK 20

____________

100

[dark blue, moss green, brick red, yellow ochre]

For color add...

Dark blue: + Cobalt Carbonate 3%

Moss green: + Chrome 1%

Brick red/warm brown: + Red Iron Oxide 15%

Golden/Yellow Ochre: + Rutile 8%

Friday, March 2, 2012

Low Fire Friday - Todd's Texture

Todd's Texture - Cone 04

Gerstley Borate 30

Zircopax 40

Whiting 20

EPK 10

______________

100

[Base, mint green, light turquoise, turquoise]

For color add...

mint green: + chrome oxide 0.5%

light turquoise: + copper carbonate 1%

turquoise: + copper carbonate 5%

[Detail, light turquoise]

PS - Anyone happen to know who Todd is? I got this recipe off of a list from somewhere years ago, and have no idea who he is. But he makes a great glaze!

Subscribe to:

Posts (Atom)